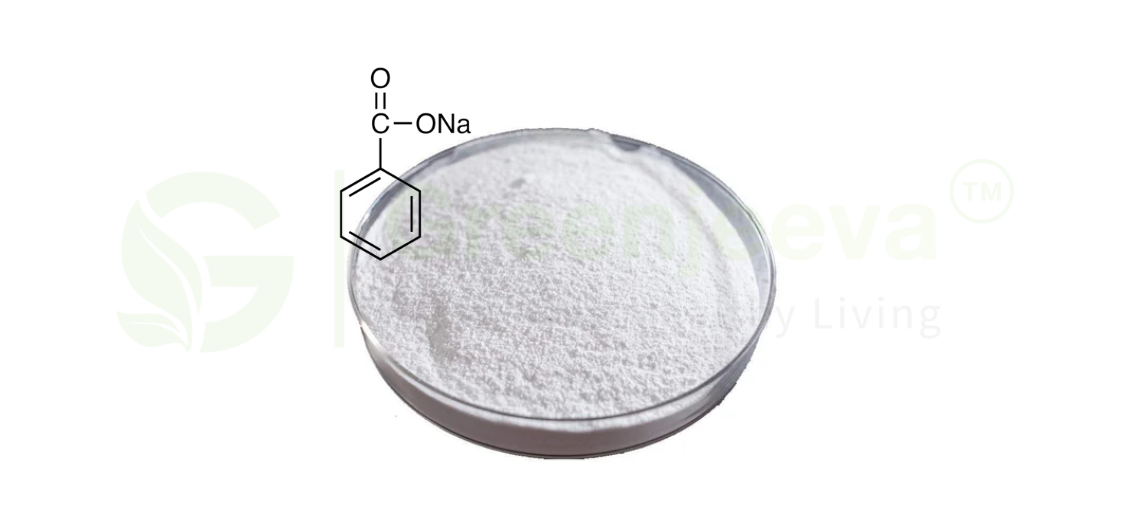

Sodium Benzoate Powder in Food Preservation: A Must-Have for Manufacturers

In today’s competitive food and beverage industry, the role of preservatives like sodium benzoate powder in preserving product quality and extending shelf life cannot be overstated. These preservatives have become indispensable tools for manufacturers aiming to protect their products from spoilage and microbial growth. Sodium benzoate's role as a reliable preservative helps businesses avoid significant losses due to product degradation, particularly in environments where bacterial or fungal contamination is risky. For manufacturers, this means maintaining product integrity while maximizing efficiency in production and distribution.

A report by MarketsandMarkets estimates that the global food preservatives market will reach USD 3.2 billion by 2025, with a growing demand for chemical preservatives like sodium benzoate. This trend is driven by the need for longer-lasting products that meet consumer safety expectations. Additionally, research from the Journal of Food Science demonstrates that sodium benzoate can extend the shelf life of beverages by up to 45%. Thus, making it an invaluable ingredient for manufacturers aiming to optimize production efficiency.

Sodium Benzoate Powder in Food Preservation

Sodium benzoate powder is a widely recognized food preservative used primarily to inhibit the growth of bacteria, mold, and yeast. Its effectiveness is particularly notable in acidic food products like carbonated beverages, fruit juices, salad dressings, and condiments, where pH levels are conducive to microbial activity. Sodium benzoate, when dissolved, breaks down into benzoic acid, which interferes with the ability of microorganisms to grow and multiply.

From a manufacturing standpoint, sodium benzoate offers more than an extended shelf life. It also ensures that food products maintain their taste, texture, and overall quality during storage and transportation. This stability is essential in an age where long supply chains and global distribution networks require products to stay fresh for extended periods.

Why Sodium Benzoate Powder is a Must-Have for Manufacturers

Cost-Effective Shelf Life Extension:

Food waste is one of the biggest concerns for manufacturers, especially when it comes to perishable products. Using sodium benzoate powder as a preservative can significantly reduce the risk of spoilage, thereby minimizing the financial losses associated with wasted goods. Its low cost compared to other preservatives makes it an economical choice, especially for large-scale production lines, and a key factor in cost-effective shelf life extension.

Product Safety & Compliance:

As a preservative approved by the FDA and EFSA, sodium benzoate complies with global food safety standards, making it suitable for a wide range of products. Its safety profile ensures that food and beverage companies can confidently include it in their formulations without compromising consumer health. Moreover, sodium benzoate does not alter the flavor profile of food products when used within recommended limits, which is crucial for maintaining product consistency.

Adaptability Across Food Categories:

One of sodium benzoate’s major advantages is its versatility. It is commonly used in acidic products such as soft drinks, jams, pickles, and syrups. Its effectiveness in liquid and powder forms makes it adaptable to various applications. Thus, allowing manufacturers to use a single preservative across multiple product lines. This simplifies procurement and inventory management and underscores its adaptability across food categories.

Improved Supply Chain Efficiency:

With sodium benzoate powder extending the shelf life of products, manufacturers can better manage their production and distribution timelines. Products can be stored for longer periods. This reduces the pressure of constant replenishment and allowing companies to strategically optimize their supply chain. For businesses dealing with long-distance transportation, this extended shelf life also reduces the risk of spoilage during shipping, thereby increasing profitability.

Compliance and Safe Usage in Food Products

The safety of sodium benzoate powder is backed by rigorous regulatory oversight. The U.S. Food and Drug Administration (FDA) and the European Food Safety Authority (EFSA) approve using sodium benzoate in food and beverages up to 0.1% concentration by weight. This ensures that products containing sodium benzoate are safe for consumption as long as manufacturers adhere to the recommended guidelines.

Manufacturers must comply with these regulations to maintain consumer trust and avoid potential legal issues. By working closely with quality assurance teams, companies can ensure that the use of sodium benzoate powder in their formulations is well within the permissible limits while achieving optimal preservative effects.

Meeting Market Demands with Sodium Benzoate Powder

The increasing demand for convenience foods and beverages has made preservatives like sodium benzoate more critical. In particular, ready-to-drink beverages, processed fruits, and condiments often rely on sodium benzoate to maintain freshness over long periods. As consumer preferences shift toward products with longer shelf lives and consistent quality, sodium benzoate will continue to play a vital role in meeting these expectations.

Also Know More: Sodium Hyaluronate Powder

An Essential Ingredient for Success

For food and beverage manufacturers, using sodium benzoate powder is not just about extending shelf life. It’s about ensuring product quality, safety, and cost-efficiency. With its proven effectiveness in preserving various food products, sodium benzoate remains a go-to solution for manufacturers looking to optimize production and distribution processes.

By incorporating sodium benzoate into their preservative strategies, manufacturers can reduce spoilage, enhance product stability, and meet the growing demands of a global market. For companies aiming to stay competitive, sodium benzoate powder is a must-have ingredient in their food preservation toolkit.

**The Food and Drug Administration has not evaluated these statements. This product is not intended to diagnose, treat, cure, or prevent any disease.**