Why Pharmaceutical Companies are Relying on Microcrystalline Cellulose Powder for Tablet Formulation

Microcrystalline cellulose (MCC) powder has established itself as an indispensable excipient in pharmaceutical tablet formulations. Its exceptional functional properties have made it a key ingredient for pharmaceutical manufacturers and nutraceutical producers looking to enhance the quality, efficiency, and appeal of their products. As the pharmaceutical industry continues to evolve, there is a growing reliance on materials that can deliver multiple benefits while ensuring cost-effectiveness, regulatory compliance, and consumer safety. This is where MCC powder stands out.

In this article, we explore the advantages of microcrystalline cellulose powder in tablet formulations, examining its binding, bulking, and disintegrating properties that have made it the go-to choice for pharmaceutical companies and clean-label supplement manufacturers. We will also delve into how bulk MCC powder suppliers are meeting the growing demand for this versatile ingredient.

What is Microcrystalline Cellulose Powder?

Microcrystalline cellulose is a purified form of cellulose derived from plant fibers, specifically wood pulp. It undergoes a controlled hydrolysis process to break down larger cellulose molecules into smaller, crystalline structures. The result is a fine, white powder that is odorless and tasteless, making it ideal for use in tablet and capsule formulations.

Its unique structure gives MCC its remarkable functional properties, including excellent compressibility, binding capabilities, and disintegration rates. These properties make it a valuable excipient in the production of pharmaceutical tablets and dietary supplements.

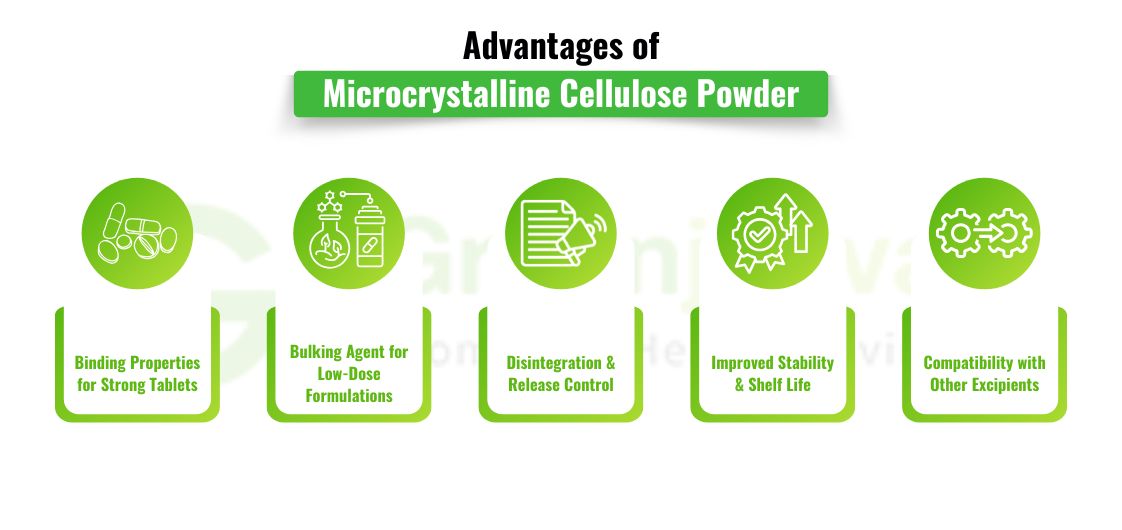

Advantages of Microcrystalline Cellulose Powder

Pharmaceutical companies rely heavily on the versatile properties of MCC powder, which improve the functionality, stability, and appearance of tablet formulations. The following benefits explain why MCC is a preferred ingredient for tablet manufacturing:

1. Binding Properties for Strong Tablets

One of the most important functions of MCC powder is its ability to act as a binder in tablet formulations. Binding agents help hold the various ingredients—such as active pharmaceutical ingredients (APIs), fillers, and excipients—together in a cohesive form. For pharmaceutical products, a strong tablet is essential to ensure that it can withstand handling, transportation, and storage without breaking or chipping.

MCC provides the necessary cohesion for solid oral dosage forms, ensuring that tablets maintain their integrity throughout the production and distribution process. As a result, manufacturers can reduce the chances of defects or loss of product quality, which is crucial in meeting regulatory standards and ensuring patient safety.

2. Bulking Agent for Low-Dose Formulations

Another significant advantage of microcrystalline cellulose is its ability to serve as a bulking agent. Pharmaceutical tablets often contain potent active ingredients in low doses, making it essential to add excipients like MCC to increase the bulk of the tablet without compromising its performance.

By using MCC as a bulking agent, manufacturers can create tablets that are large enough for ease of handling, while still maintaining an accurate dosage of the active ingredient. This is particularly important for clean-label supplements and nutraceutical manufacturers, where consumers expect accurate dosages and functional benefits.

3. Disintegration and Release Control

The disintegration properties of MCC powder are another reason pharmaceutical companies favor it in tablet formulations. After ingestion, tablets must break down efficiently in the gastrointestinal tract to release their active ingredients for absorption. MCC ensures that tablets break apart at the right time, facilitating rapid dissolution and improving the bioavailability of the active compounds.

This disintegration function is particularly useful for time-release or controlled-release formulations, where it’s important for the tablet to release its contents gradually. MCC plays a critical role in ensuring that the tablet disintegrates in a controlled manner, thereby optimizing therapeutic efficacy and patient experience.

4. Improved Stability and Shelf Life

Microcrystalline cellulose is a stable substance that doesn’t interact negatively with moisture or oxygen, making it a reliable excipient for enhancing the shelf life of pharmaceutical products. In a world where pharmaceutical companies need to ensure long-lasting product stability, MCC helps maintain the potency of tablets over extended periods.

This stability is particularly valuable for manufacturers aiming to meet the regulatory requirements for shelf-life testing. Since MCC is highly resistant to changes in environmental conditions, it helps ensure that tablets retain their intended performance from production to consumption.

5. Compatibility with Other Excipients

MCC powder is highly compatible with a wide variety of other excipients commonly used in tablet formulations. These include fillers, colorants, sweeteners, and lubricants. This compatibility makes MCC a versatile choice for manufacturers who need to create complex tablet formulations while ensuring the consistency and efficacy of their products.

The adaptability of MCC allows pharmaceutical companies to formulate tablets with different release profiles, flavors, and colors, all while maintaining the same base structure. This makes it a preferred option for a broad range of pharmaceutical products and nutraceutical supplements.

Why Bulk MCC Powder Suppliers Are Crucial to Pharmaceutical Manufacturers

The growing demand for microcrystalline cellulose powder is largely driven by pharmaceutical companies, nutraceutical manufacturers, and clean-label supplement producers who seek high-quality, reliable ingredients for tablet formulation. Bulk MCC powder suppliers play a crucial role in providing pharmaceutical manufacturers with the quantities they need to meet production schedules and regulatory standards.

1. Ensuring Quality and Consistency

Bulk MCC powder suppliers must meet stringent quality control standards to ensure that their products are free from contaminants and meet regulatory requirements. For pharmaceutical companies, consistency in excipient quality is paramount to ensuring the safety and efficacy of their products. Suppliers who can reliably deliver high-quality MCC powder with minimal variation in particle size, moisture content, and bulk density are invaluable partners for manufacturers.

2. Cost-Effectiveness and Efficiency

For pharmaceutical manufacturers, using bulk MCC powder from trusted suppliers helps reduce costs, streamline production processes, and ensure optimal use of resources. Bulk suppliers can offer competitive prices for MCC powder, which can significantly lower the cost of tablet formulation, especially when producing large batches.

Furthermore, bulk MCC powder suppliers can offer faster lead times and ensure a steady supply of material, enabling manufacturers to meet market demand without delays.

The Role of MCC in Clean-Label Supplements and Nutraceutical Manufacturing

The trend toward clean-label supplements has put additional pressure on manufacturers to use high-quality, natural ingredients with minimal additives or fillers. MCC, being derived from plant sources, meets the growing demand for clean-label supplements and natural products. It’s an ingredient that consumers can trust because it is simple, effective, and safe.

For nutraceutical manufacturers, MCC provides a functional, effective, and non-synthetic excipient that meets consumer expectations for transparency. Additionally, MCC’s bulking and disintegration properties enhance the performance of nutraceutical products, whether in the form of tablets, chewables, or effervescent formulations.

As the nutraceutical market continues to grow, bulk MCC powder suppliers are increasingly meeting the needs of manufacturers who require a high-quality, functional ingredient to create innovative, consumer-friendly products.

Conclusion

Microcrystalline cellulose powder has earned its reputation as one of the most essential excipients in the pharmaceutical industry. Its binding, bulking, and disintegrating properties make it an ideal choice for tablet formulation, ensuring the stability, quality, and efficacy of pharmaceutical products. As the demand for clean-label supplements and functional ingredients grows, MCC remains a key player in enhancing the performance of nutraceutical formulations.

For pharmaceutical companies, nutraceutical manufacturers, and clean-label supplement producers, the role of bulk MCC powder suppliers is crucial in providing a steady, reliable supply of this versatile and cost-effective ingredient. Whether for use in pharmaceutical products, dietary supplements, or functional ingredients, microcrystalline cellulose continues to be a preferred choice for enhancing the quality and performance of tablets, capsules, and other dosage forms.

**The Food and Drug Administration has not evaluated these statements. This product is not intended to diagnose, treat, cure, or prevent any disease.**

.jpg)